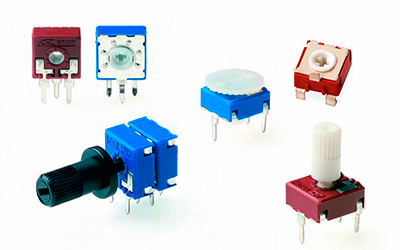

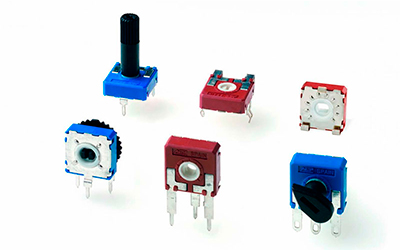

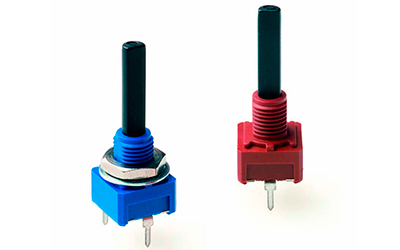

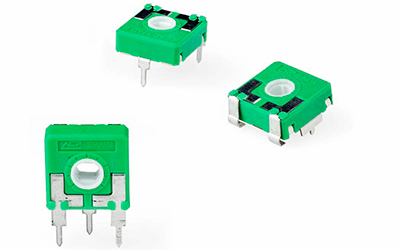

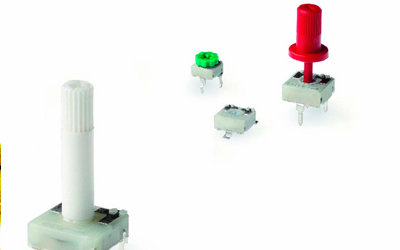

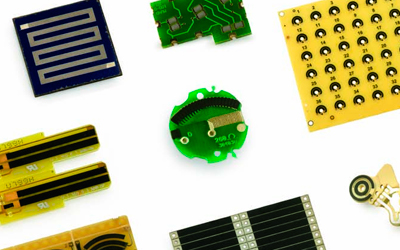

ACP develops trimmers, sensors, control potentiometers, rotary switches and customized services in the field of passive components. We want to make a difference, so we work close to our customers to develop special products tailored to their needs.

Aragonesa de Componentes Pasivos, S. A. (ACP), based in Tarazona (Zaragoza) Spain, is a World recognized specialist in thick-film technology and its application in the field of variable resistance since 1988. Our products include angular position sensors, potentiometers and trimmers which can be found in the following markets: Appliances, Industrial, Multimedia and Automotive.

ACP’s expertise lays in the development, characterization and manufacturing of polymeric pastes (resistive, conductive and dielectric) and its deposition in a wide range of substrates. We are vertically integrated, we also design and manufacture the plastic and the metal components that make part of our final products, being experts in materials and manufacturing processes. Finally, we put together all these components in our automated assembly lines that feature the control of the electrical parameters of each and every finished product.

This expertise allows us to adapt our products for customers with special and demanding requirements, providing electromechanical tailor made solutions.

Our products are RoHS and Reach compliant, and we are certified by IQNet under ISO 9001 and ISO/TS 16949.

ACP has a strong R&D department that includes mechanical, chemical, materials, electronics and electrical engineers and also holds collaborations with universities and research institutes. We count with a professional team that makes our flexibility and high service level a key part of our value proposition. Our Prototype Building Team is able to prepare samples in very short lead time.

Equipment:

- In-house designed fully automated assembly lines, with integrated automated control systems.

- Type C clean room (class 10.000), with screen-printing equipment.

- On line drying, curing and sintering furnaces.

- Convection curing furnaces.

- Laser trimmer.

- Reel to reel electroplating.

- Dies and presses for metal strip stamping.

- Plastic injection machines.

- Quality testing laboratory: climate chambers, profile projectors, mechanical life equipment, shakers...

Sometimes we have ideas that seem to clash with the world, as we know it. But if we are willing to take a different approach and look at things from a different point of view; they might become a reality.

This way of thinking confirms what we understood at ACP some time ago: to be innovative we need to look at things from a different perspective, we need to challenge the established standards.

Facing this situation, we have reversed the first rule of industrial production: instead of designing to manufacturing, we manufacture for design. It is the only way to make ideas and the reality compatible and to come up with advanced concepts... We do know that there is no more powerful tool than imagination.